Motor de Plasma.

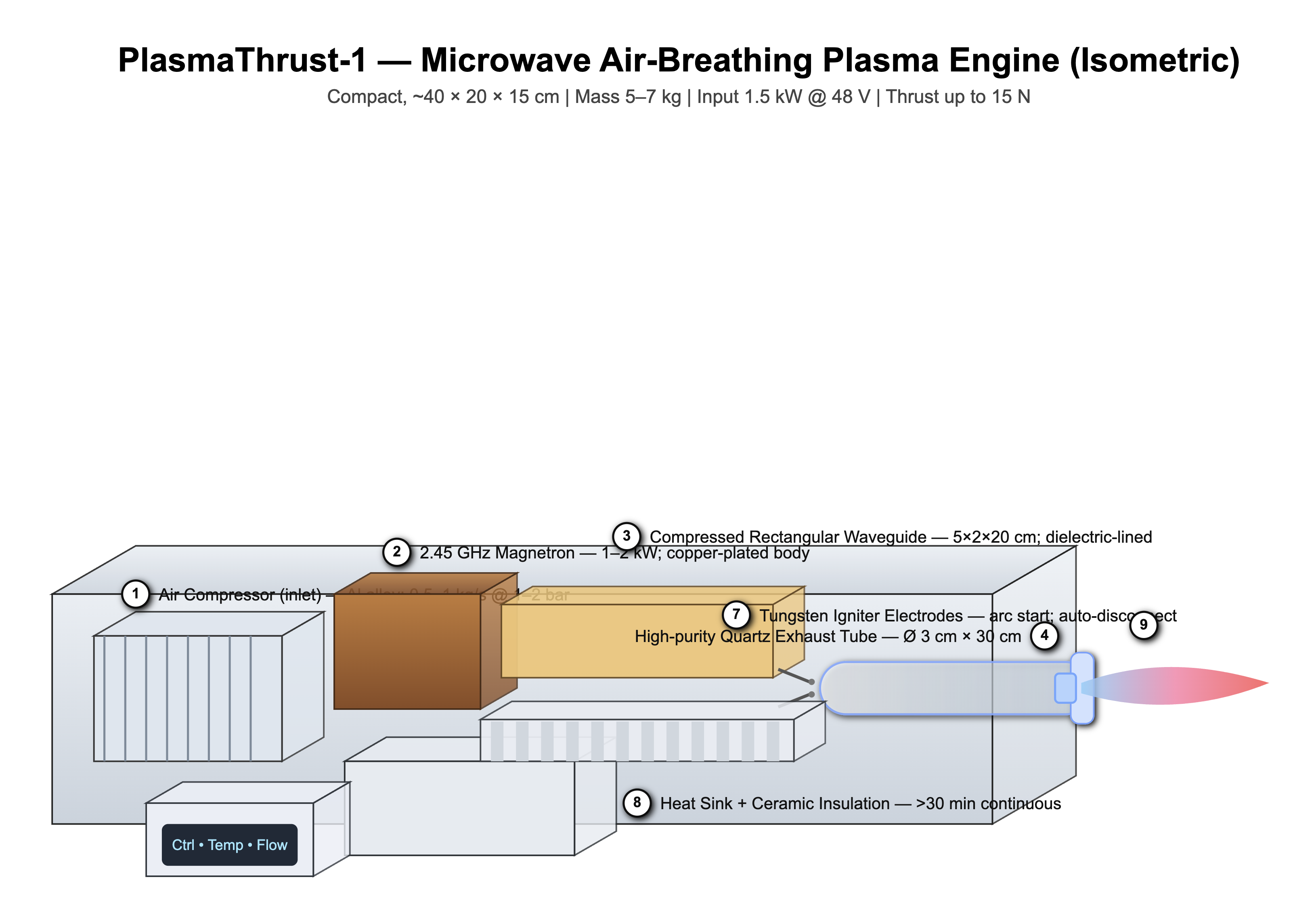

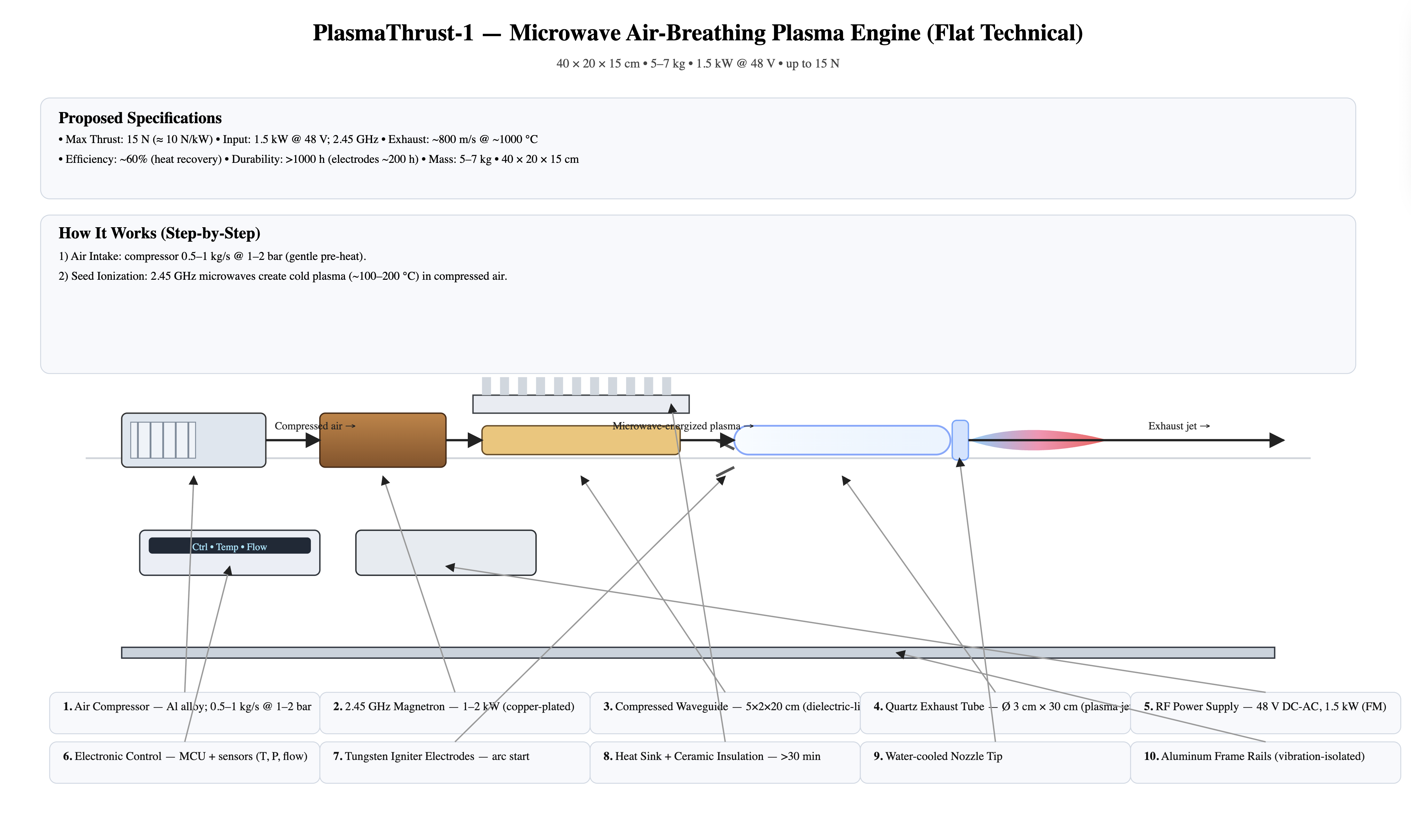

PlasmaThrust-1 — Microwave Air-Breathing Plasma Engine (Isometric)

Key Components (numbered on the diagram)

-

Air Compressor (inlet) — Lightweight Al alloy centrifugal stage; 0.5–1 kg/s @ 1–2 bar

-

2.45 GHz Magnetron — 1–2 kW copper-plated body; microwave source

-

Compressed Rectangular Waveguide — 5 × 2 × 20 cm, dielectric-lined; field concentration

-

Quartz Exhaust Tube — Ø 3 cm × 30 cm, high-purity quartz; plasma containment

-

RF Power Supply (48 V DC-AC) — 1.5 kW with frequency modulation

-

Electronic Control (MCU + sensors) — Temp/pressure/flow; real-time control

-

Tungsten Igniter Electrodes — Arc start; auto-disconnect after stable plasma

-

Heat Sink + Ceramic Insulation — Fins + ceramics; continuous > 30 min

-

Water-cooled Nozzle Tip — Safety & durability at ~1000 °C exhaust

-

Aluminum Frame Rails — Vibration-isolated mounting

How it works (isometric flow)

-

Air intake: Compressor provides 0.5–1 kg/s at 1–2 bar.

-

Seed ionization: Magnetron injects 2.45 GHz power to form cold plasma (?100–200 °C).

-

Heating & acceleration: Flattened waveguide concentrates EM field; collisions raise temperature toward ~1000 °C.

-

Arc assist: Tungsten electrodes trigger ignition, then disconnect once plasma is self-sustaining.

-

Expansion & thrust: Pressurized plasma expands through the quartz tube/nozzle, producing a jet (~Mach 1–2).

-

Control loop: MCU modulates RF power and monitors T/P/flow to stabilize thrust and prevent overheat.

Proposed specifications

-

Max thrust: ~15 N (? 10 N/kW)

-

Input power: 1.5 kW @ 48 V; 2.45 GHz

-

Exhaust velocity: ~800 m/s

-

Exhaust temperature: ~1000 °C (cooled tip)

-

System efficiency: ~60% (with heat recovery for pre-heat)

-

Durability: > 1000 h (electrode service ~200 h)

-

Mass & envelope: 5–7 kg; 40 × 20 × 15 cm

Notes

-

The PNG shows a true isometric-style layout with callouts, flow arrows, a color-graded plasma plume, and a scale bar (0–40 cm).